Spray Performance

You know what pesticides you need and when to use them, but what other factors do you need to consider for the best spray performance? Knowing how to achieve the best spray quality can help you maximize profits on your farm.

To be effective, a certain amount of a pesticide must remain on a leaf surface. The deposit pattern depends on the droplet size, spray direction, droplet velocity at the point of impact, physical properties of the spray mixture, and characteristics of the leaf surface.

4 important factors:

Pesticide

Choice

Application Equipment

Application Time

Spray

Quality

The importance of droplet size

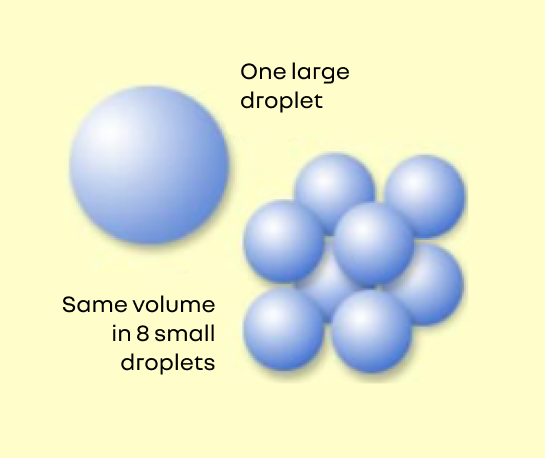

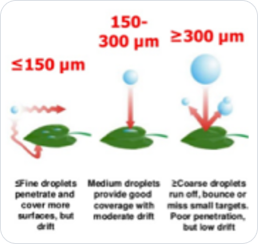

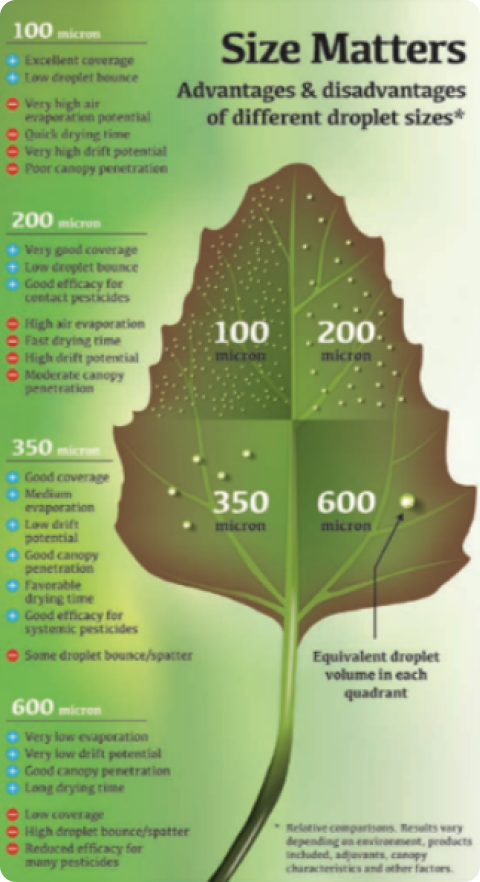

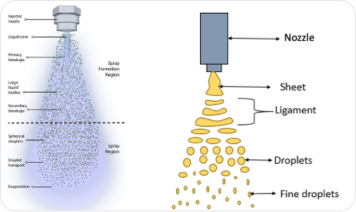

The small droplets shown here are below 150 microns in diameter. Small droplets have a low terminal velocity. Their low kinetic energy causes them to decrease speed faster and float longer. Smaller droplets cover more surface area on the plant and have greater droplet density. Without some form of air assistance, however, they can evaporate or drift away from the target, resulting in poorer performance for you and potentially damaging crops in your neighbor’s field.

The larger droplets that are shown here are above 300 microns and have a high terminal velocity. Their relatively greater mass and higher speed make it easier to manage their trajectory and to reach the target. However, these droplet sizes hit the plant at higher speeds and with greater momentum, which means that they tend to have undesirable aspects of bounce, shatter, and runoff. This reduces their retention on leaf surfaces. If the leaf retains fewer droplets, then the pesticide’s performance is significantly reduced.

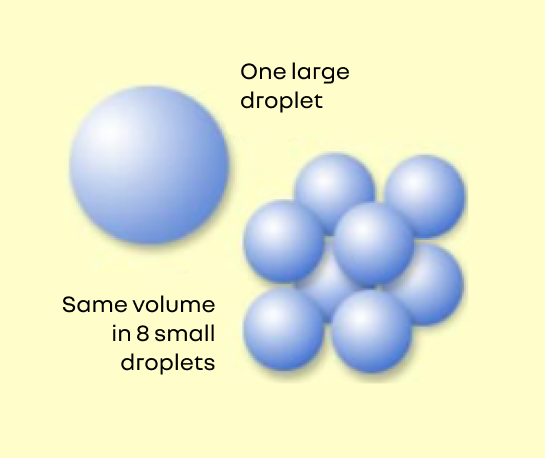

One large droplet of 400 microns contains the same volume as 8x 200 micron droplets. Spraying coarse droplets means you often need to increase your water volume to create a sufficient number of droplets.

Large droplets are ideal for spraying pre-emergent herbicides onto bare soil, but they are not suitable for use when spraying fungicides and insecticides where contact is important for product efficacy.

For pesticides to work effectively, the target area needs to retain a minimum amount of spray mixture at sufficient concentration for plant uptake. The ideal droplet size for this is 150 – 300 microns. This sweet spot produces droplets that have sufficient momentum to overcome drift and get down to the plant canopy, but they are small enough to stay on the plant surface upon impact.

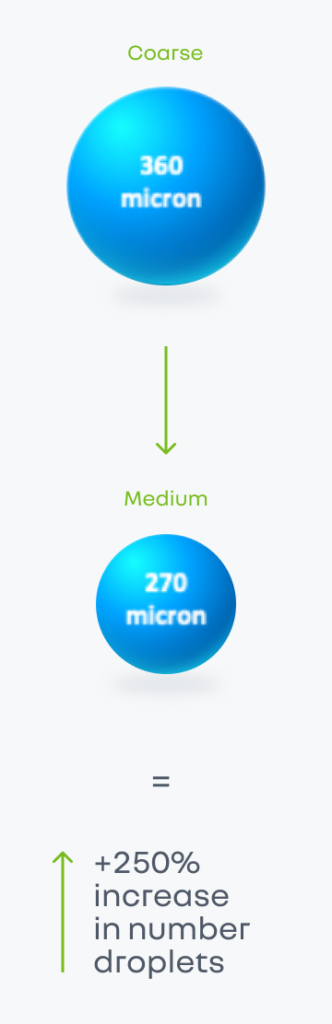

Even a small change in droplet size from a coarse to a medium droplet will result in a 250% increase in the number of droplets that are sprayed.

The importance of nozzle size

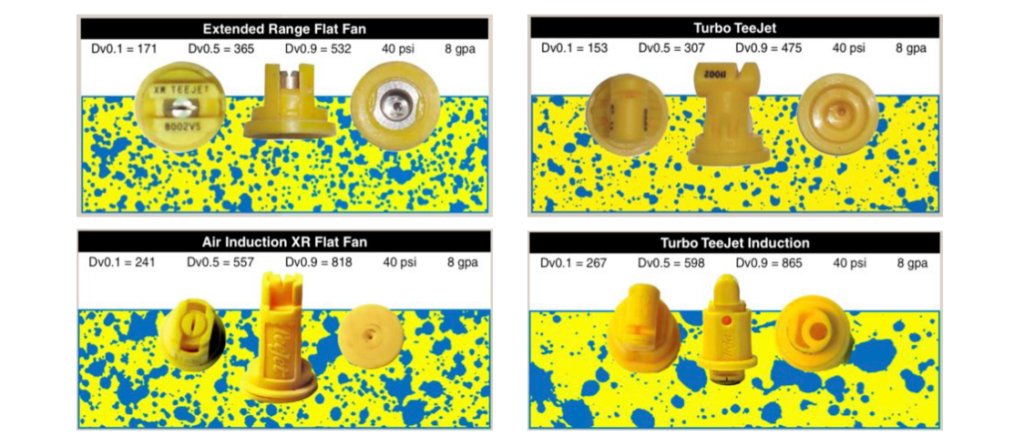

Different Drift Reduction nozzles produce different droplet distribution

A key question to ask yourself when filling up your spray tank, is how many gallons of liquid in your tank will actually reach the target and then be retained on the leaf surface.

The importance of application rate

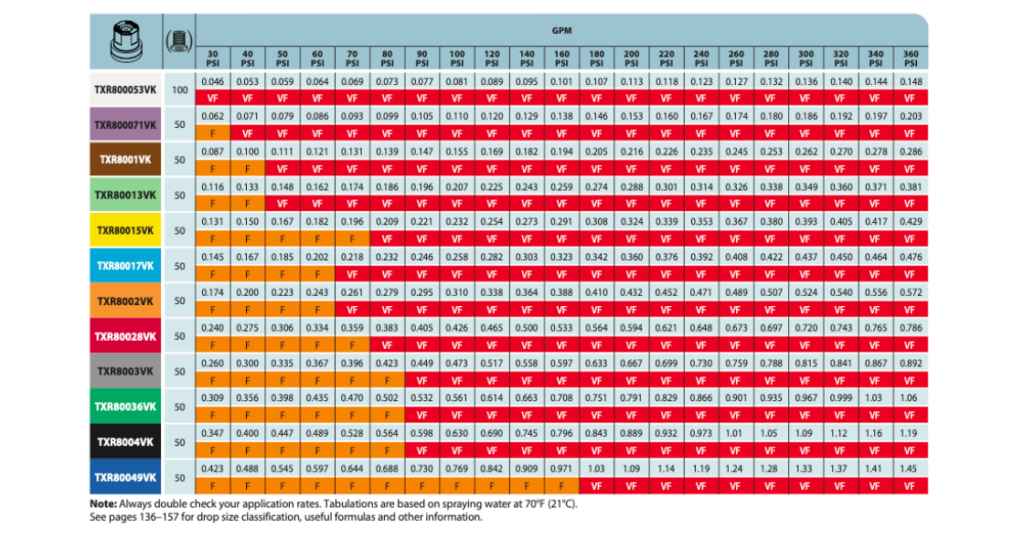

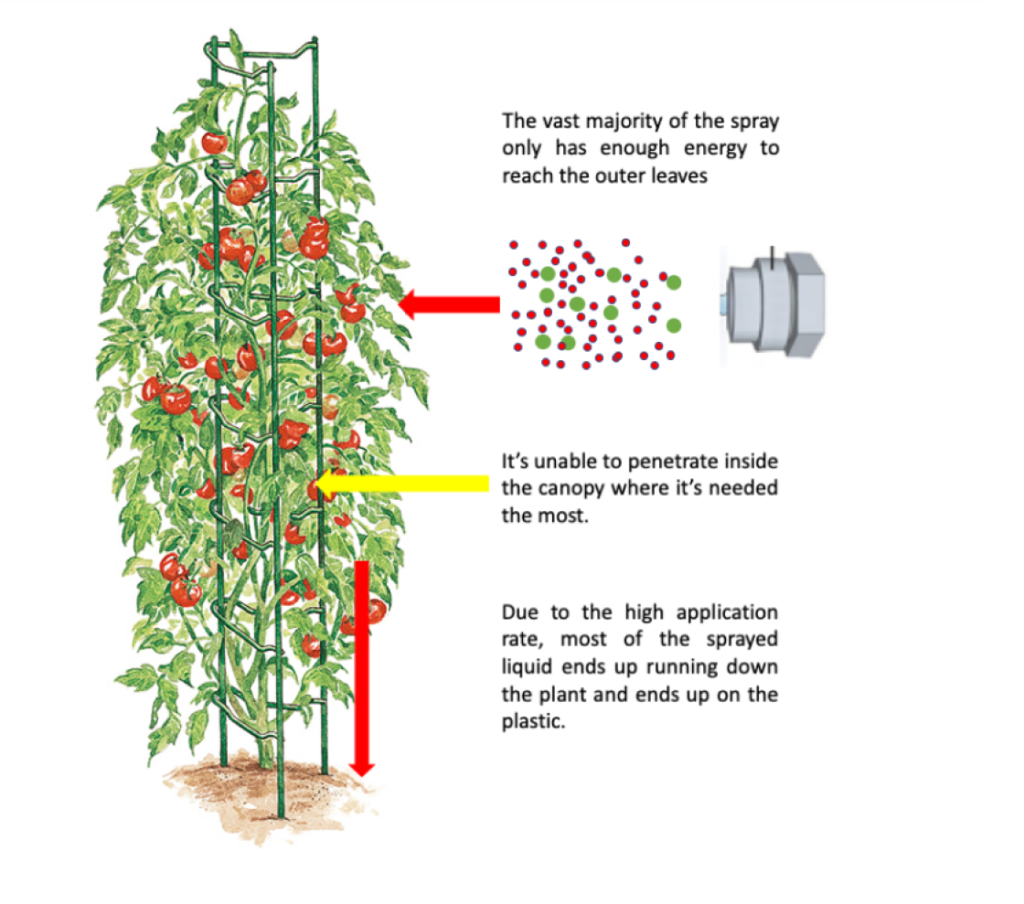

Often growers increase pressure as a way to increase their application rate, but this is actually a counter-productive step. Doubling the pressure only results in a 40% increase in application rate, but it also significantly increases the amount of driftable droplets. For example, some growers use pressures in excess of 150psi for their high value crops and apply application rates of 100-200 gpa. Without some form of air to push the spray into the canopy, though, the spray is not getting into the right area.

How MagrowTec can help

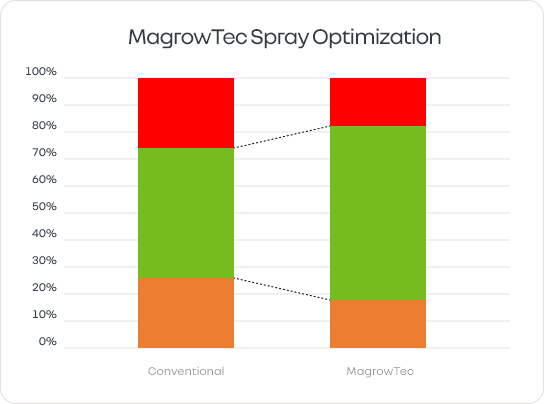

The MagrowTec system helps by creating more of the optimum spray – ensuring that more of the spray goes onto the weeds, crop canopy, buds, flowers, stalk, fruit or vegetable product itself or soil, giving better coverage and more protection.

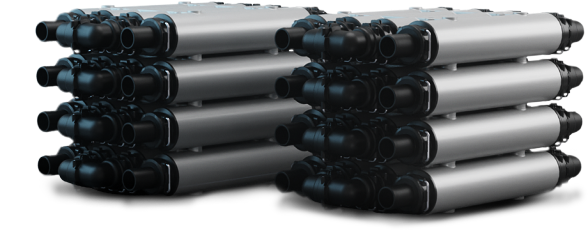

While adjuvants are physical products that are added to the tank mix, the MagrowTec system is a hardware solution that is fitted onto the sprayer itself to condition the fluid as it passes from the tank to the nozzle. The flow of the fluid past static magnetic fields at the appropriate flow conditions changes the physical properties of the spray fluid, creating more of the optimum-sized spray during the atomization process.The conditioned fluid passes through a series of manifolds, containing permanent rare earth magnets similar to those used in electric cars. There are numerous contributing factors, related to the magnetic effect and resultant changes in the physical properties of the fluid delivering the unique spray characteristics and associated benefits. We call this the MagrowTec effect.

The product itself comprises of just two simple components.

The product is a completely passive plumbing system with no moving parts or wires and the magnets only lose 1% of their total strength over 15 years.

The kit can be installed onto a sprayer by 2 people in around 6 hours and can be removed in around 1 hour meaning that it can be easily transferred onto a new sprayer when you’re trading in your sprayer.

The product is modular and so if your new sprayer has a longer boom you only need to purchase some extra rods for your spray line.

There is virtually no configuration or maintenance required. Each manifold only holds 0.5 gallons (2 litres) and so regular flushing practices between sprays is sufficient.

Each rod only weighs 1.5 lbs and so the added weight on a 120’ sprayer is only 110lbs across the entire boom.

MagrowTec Benefits

They can use a 20-30% lower application rate with the MagrowTec system to achieve the same coverage as their regular sprayer.